Assessing varied food manufacturer’s waste for further valorisation as industrial biotechnology feedstock

- Project lead

- James Winterburn

- Institute

- The University of Manchester

Summary:

Unavoidable byproducts/wastes from food manufacturing could provide an important source of nutrients for fermentation process. Substitution of purified substrates typically used in industrial biotechnology could provide the increased market competitiveness needed by a number of sustainable products such as biopolymers and biosurfactants. Existing research on the valorisation of food manufacturing byproducts/wastes typically focused on streams with little variable. However, a significant portion of these waste streams exists as mixed wastes with significant daily variability.

Pro Pak Foods is a retorted ready meal manufacturer who make around 500,000 ready meals a week, which can lead to wastes with a highly variable content of raw and booked carbohydrates, proteins, fats, animal, and vegetable. In this collaboration with the University of Manchester, a varied range of food wastes will be subjected to a thermochemical and/or enzymatic treatments. The ability of the resulting hydrolysate stream to act as a source of sugars, fatty acids and/or nitrogen will then be assessed using a panel of microorganism producer of biopolymers/biosurfactants; with the aim of finding empirical relationships between the varying nature of the food wastes, the processing/treatment methods and the fermentation scheme/final product. The insights from this collaboration may allow industrial biotechnology to tap into an underutilised feedstock, whilst providing our industrial partner with a new avenue of valorising their unavoidable wastes.

Aims:

Unavoidable byproducts/waste from food manufacturing could provide an important source of nutrients for fermentation and production of bioproducts. This project aims to quantify the variability of hydrolysate produced from food manufacturing wastes and screen their viability for biopolymers and biosurfactants production, to identify empirical relationships between the types of substrate variability in food wastes and the fermentation process that may allow industrial biotechnology to tap into these underutilised feedstocks, whilst providing new avenues of valorising unavoidable wastes.

Objectives:

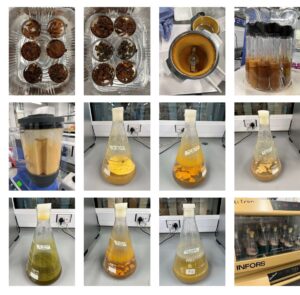

Six different waste streams with different types and proportion of meat, vegetable and starch provided by the industrial collaborators were characterised, allowing for assessment of the degree of variation in sugars, carbon and nitrogen seen in food manufacturing waste to be quantified. The wastes were then hydrolysed using enzymes and screened using a panel of bacteria, archea and yeast for the production of polyhydroxyalkanoate biopolymers and sophorolipid biosurfactants. Whilst all streams were largely viable for producer growth and bioproduct formation, different streams were found to be more suitable for each producer, due to differences in substrates available.

Impact:

Parameters for successful use of high variability food waste for the tested bioproduct/organisms were identified. Media standardisation strategies were identified for improved use of food waste-derived media in industrial biotechnology, which could provide cheaper feedstocks for the biotechnology and added values for the food industry on their unavoidable food wastes.

Academic partner: James Winterburn, The University of Manchester

Industrial partner: David Raine, Pro Pak Foods Ltd