Exploring a novel circular economy concept for the valorisation of crude glycerol from biodiesel production

- Project lead

- Alfred Fernandez-Castane

- Institute

- Aston University

Summary:

The production of biodiesel uses for example, vegetable oils and fats and; yields crude glycerol as by-product. For every 100 kg of oil converted, 10 kg of crude glycerol are produced. The purification of glycerol is complex and pure glycerol is low-priced thus, not presenting economic incentive to the biodiesel industry. However, crude glycerol can be converted into lactic acid via hydrothermal treatment. On the other hand, magnetosomes are an exciting class of iron oxide magnetic nanomaterials that are extracted from magnetotactic bacteria (MTB) and can be used for example, in biocatalysis. MTB use lactic acid for growth and energy and, to date, only lactic acid derived from petrochemicals has been employed for MTB cultivation. Argent Energy is a major UK biodiesel producer that generates 200 tonnes of crude glycerol annually and is looking for more efficient and economic ways of using this by-product.

Aim:

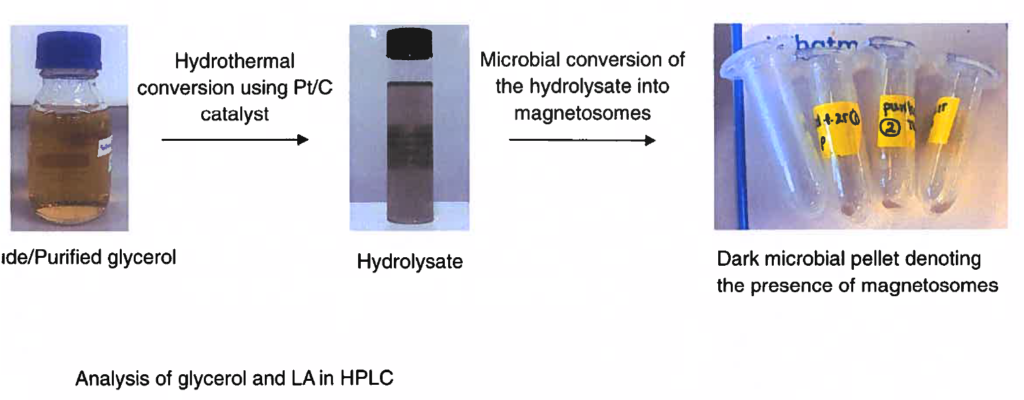

Biodiesel production generates crude glycerol as a by-product and more effienient and economic wayso fo using glycerol need to be developed. This project combines expertise in biotechnologies and hydrothermal processing from Aston University to provide added value to crude glycerol. The aim of the project is to study the feasibility of using liquefied lactic acid obtained through hydrothermal conversion of crude glycerol to grow microbes that produce magnetosomes, a high-vallue nanamaterial with a wide range of biotechnological applications.

Outcomes:

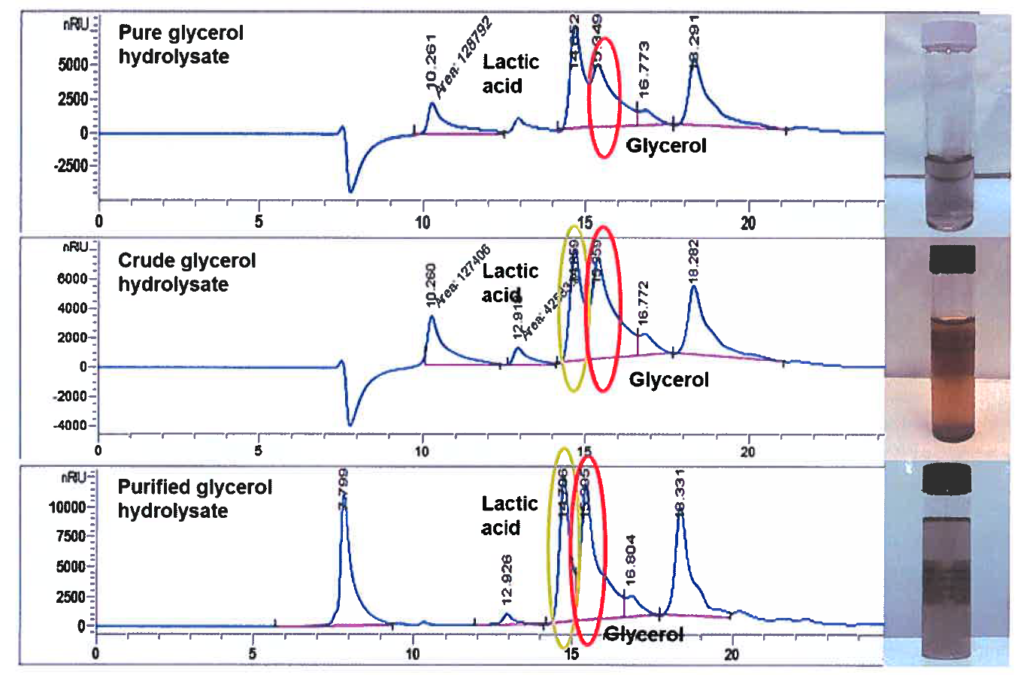

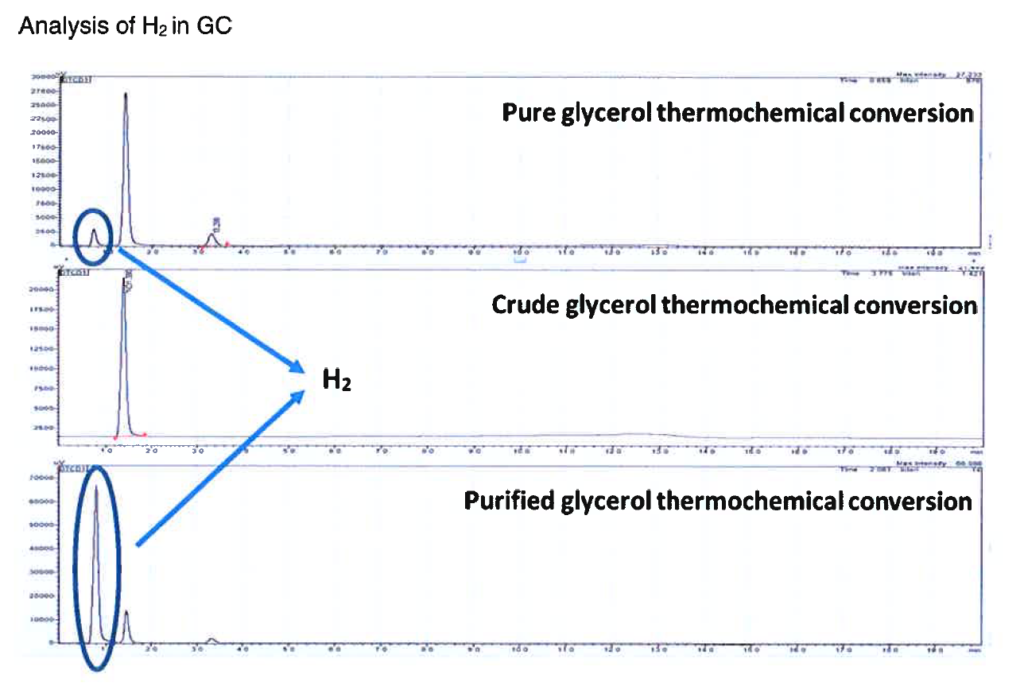

In this partnership, we have developed a new process to transform crdue glycerol, which is obtzinsed as a biodiesel by-product, into lactic acide and other organic acids. We have then used the lactic acid as a carbon source to grow magnetotactic bacteria, a class of microbes that can make nanomagnets, namely magnetosomes, that can be used in a wide range of biotechnology applications.

Impact:

We envisage that the outcomes of this research will pave the way toward a novel circular and cleaner process that reduces waste generation from the biodiesel industries combined with the production of chemicals, energy and materials for a sustainable future.

Academic partner: Alfred Fernandez-Castane, Aston University; Jude Onwudili, Aston University

Industrial partner: Martin Kingsley, Argent Energy