Mining natural and synthetic diversity towards sustainable methacrylate production

- Project lead

- Benjamin Blount

- Institute

- University of Nottingham

Summary:

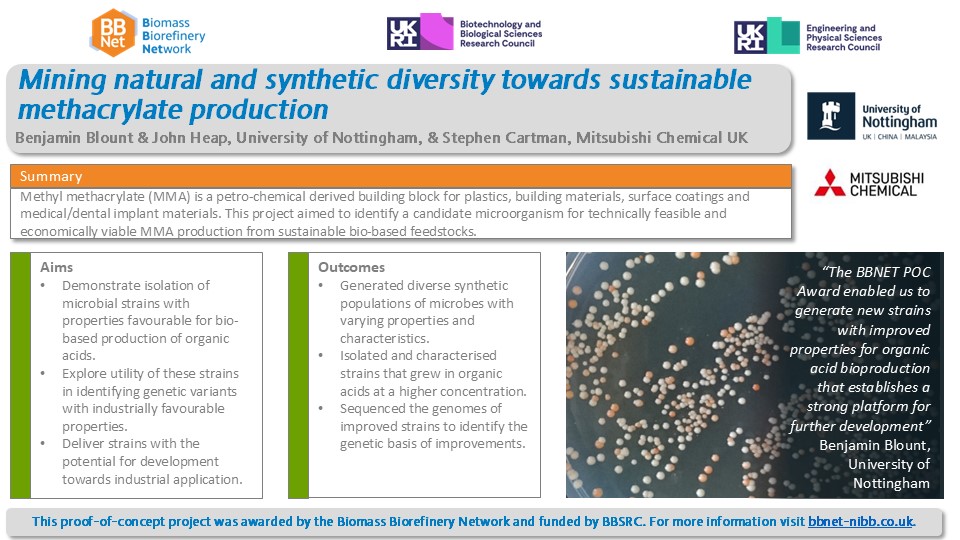

Methyl methacrylate (MMA) is a chemical building block for plastics, building materials, surface coatings and medical/dental implant materials. Currently, ~4 million tonnes (valued at ~$7.5 bn) is produced annually from petrochemicals. This produces ~14 million tonnes of associated CO2 emissions, roughly equivalent to the total annual CO2 emissions of Slovenia. We are partnering with the world’s largest MMA producer, to identify a candidate microorganism for technically feasible and economically viable MMA production from sustainable bio-based feedstocks. We will take an approach that samples microbes from environmental samples and also uses cutting edge synthetic genome techniques to create diverse populations of candidate microbes. We will subject these natural and synthetically diverse pool of microbes to stress conditions designed to allow us to artificially select cells demonstrating characteristics needed for effective industrial MMA production. This industrial biotechnology approach will lay the foundation for transitioning production of this important chemical away from petrochemical-based approaches towards sustainable low-emission bioproduction from agricultural waste feedstocks.

This project is ongoing and an update on the outcomes and impact will be published on completion.

Aims:

The aim of the proof-of-concept study was to demonstrate that we could isolate microbial strains with properties favourable for the future implementation of bio-based production of organic acids. By exploiting state-of-the-art synthetic chromosome strains with built-in gene shuffling systems, we aimed to explore the utility of these strains in identifying genetic variants with industrially favourable properties and ultimately deliver strains with the potential for development towards industrial application.

Outcomes:

We generated diverse synthetic populations of microbes with varying properties and characteristics. From this diversity, we isolated and characterised strains that were able to grow in organic acids at a higher concentration than previously characterised microbes. We have sequenced the genomes of improved strains to identify the genetic basis of improvements. This process has generated several strains with enhanced properties for industrial bioproduction of organic acids.

Impact:

Production of platform chemicals from petrochemical feedstocks is performed on a massive scale to meet our needs for plastics, building materials and coatings, but has a considerable associated CO2 output. Our new approach has produced promising strains towards development of sustainable alternative bio-based processes for the production of organic acids.

Academic partners: Benjamin Blount, University of Nottingham, Prof John Heap, University of Nottingham

Industrial partners: Stephen Cartman, Mitsubishi Chemical UK